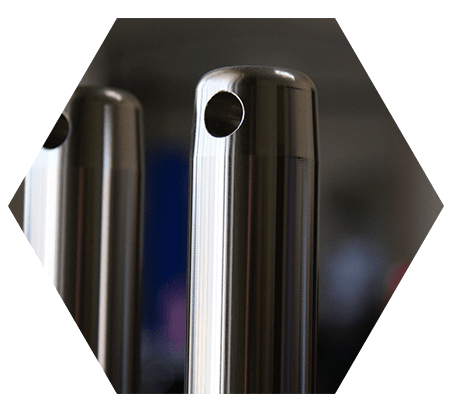

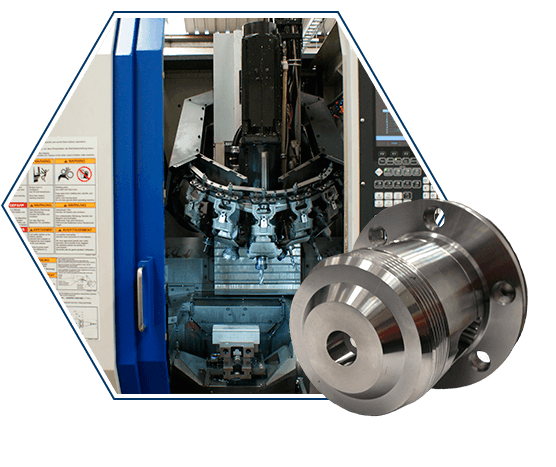

Machined

At SIIOSA we have machines with 3 to 5 axes indexed.

Algunos de los materiales que maquinamos son los siguientes:

Aluminum

Aluminum Iron

Iron Stainless Steel

Stainless Steel HJP Plastic

HJP Plastic Nylamid

NylamidLathe

Materials:

Aluminum

Aluminum

Iron

Iron

Stainless Steel

Stainless Steel HDP Plastic

HDP Plastic

Nylamid

Nylamid

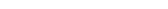

Hydro cutting

It is an environment-friendly technology.

It is an environment-friendly technology. Creates a clean and high quality cutting.

Creates a clean and high quality cutting. Cold cutting process, no need to apply heat.

Cold cutting process, no need to apply heat. No structural changes in cut materials.

No structural changes in cut materials. Practically free of burrs at the cutting edges.

Practically free of burrs at the cutting edges. It has industrial and aesthetic applications.

It has industrial and aesthetic applications.  Appropriate for cutting high performance metals

Appropriate for cutting high performance metals • Its waterjet cutting allows cutting any material except tempered glass.

• Its waterjet cutting allows cutting any material except tempered glass.Materials:

Steel

Steel Stainless Steel

Stainless Steel Aluminum

Aluminum Nylamid

Nylamid Granite

Granite Marble

Marble Titanium

Titanium Fiberglass

Fiberglass Glass

Glass Brick

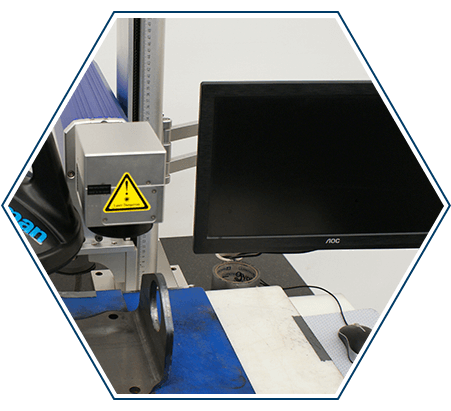

BrickLaser cut

The laser cutting offers a detailed cut, even on the hardest of steels. Complex contours, small holes and narrow bands are cut cleanly and without burrs.

Cutting metals such as:

Carbon steel, stainless and galvanized steel, and aluminum among other metals in thin gauges and up to 1 inch, without cracks, fragmentation or splinters, clean edges and squares, in turn make the most of cutting boards thanks to advanced nesting.

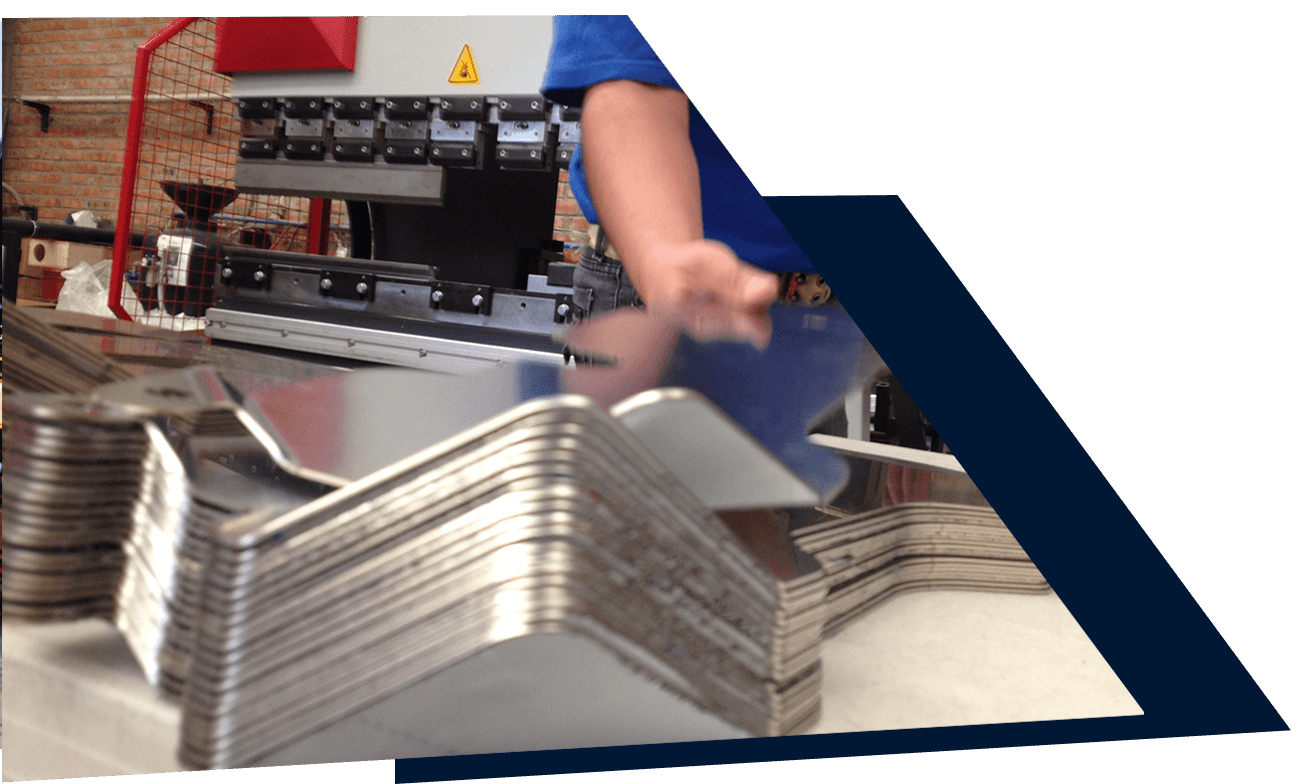

Fold

The modern folding process provides greater speed, accuracy and quality; compared to conventional systems, thanks to its advanced computerized system. The bending stresses the outer fibers of the material without causing important changes in the thickness of the material.

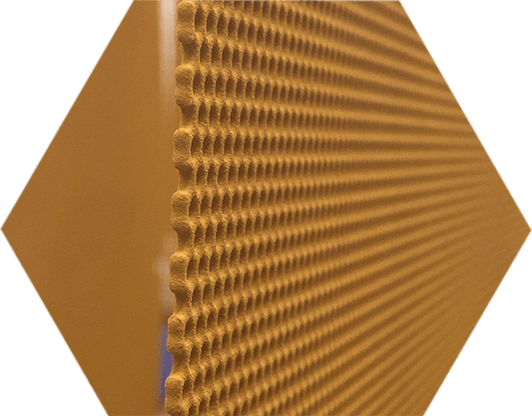

Anodize

Anodizing is an electrochemical process that creates a significantly thicker layer of oxide than the one that forms naturally.

This provides protection against mechanical deterioration and corrosion as well as transforming the surface into electrical insulation.

Our process creates a coating of 18 microns, tested in saline chamber.

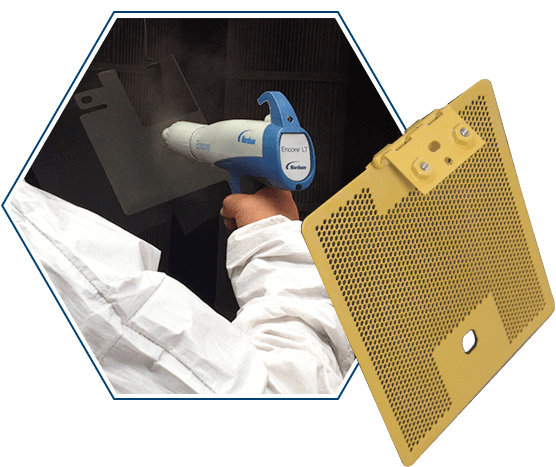

Powder Coat

The process reduces the dangerous emissions up to 92%.

The process reduces the dangerous emissions up to 92%.We have a prepared (pre-treatment) surface suitable for the specifications of each client as well as a wide range of colors and appearances.

It produces coatings with excellent resistance to corrosion, heat, impact, weathering abrasion and extreme temperature changes.

It produces coatings with excellent resistance to corrosion, heat, impact, weathering abrasion and extreme temperature changes. High gloss, semi-gloss and matte products, metallic, pearlescent and even colorless and textured effects can be achieved.

High gloss, semi-gloss and matte products, metallic, pearlescent and even colorless and textured effects can be achieved. They can be formulated for application in different thicknesses according to the specifications of the client.

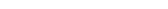

They can be formulated for application in different thicknesses according to the specifications of the client.Ecoat

The color used for Ecoat is black; however, a new color can be implemented according to the customer requirements.

The color used for Ecoat is black; however, a new color can be implemented according to the customer requirements. The ecoat effect enables you to cover the part completely regardless of the geometry as it reaches the entire surface area of the piece both inside and outside.

The ecoat effect enables you to cover the part completely regardless of the geometry as it reaches the entire surface area of the piece both inside and outside.We have tubs with a capacity of 1000 liters, which allow a piece with a maximum length of 1.2 m.

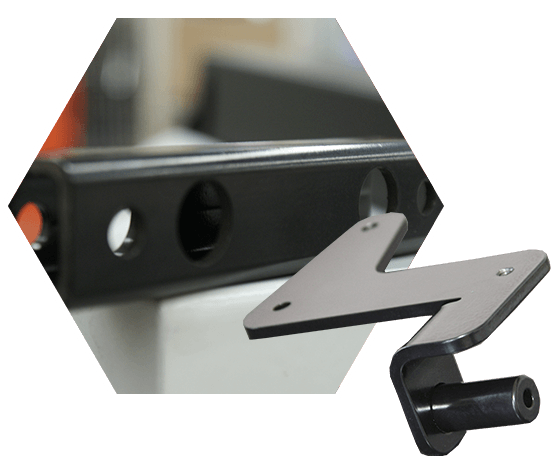

Laser etching

It is the only tool capable of providing smooth designs with complex details.

It is the only tool capable of providing smooth designs with complex details. The machine runs at maximum speed, increasing the productivity of your company. Due to the fact that there is no physical conflict with the part to be recorded, the laser slides quickly and smoothly on the surfaces and allows maximum definition in the engraving.

The machine runs at maximum speed, increasing the productivity of your company. Due to the fact that there is no physical conflict with the part to be recorded, the laser slides quickly and smoothly on the surfaces and allows maximum definition in the engraving.

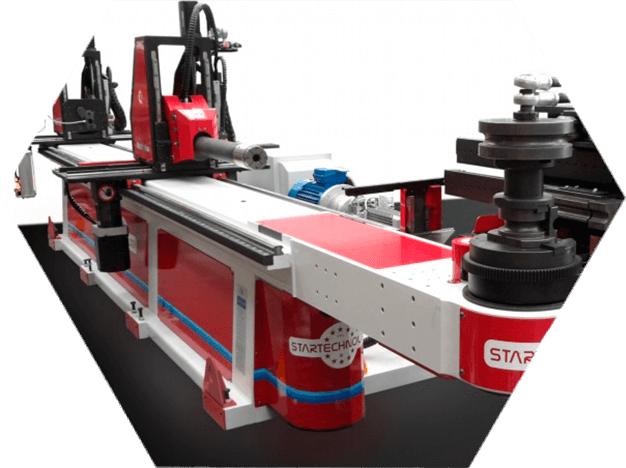

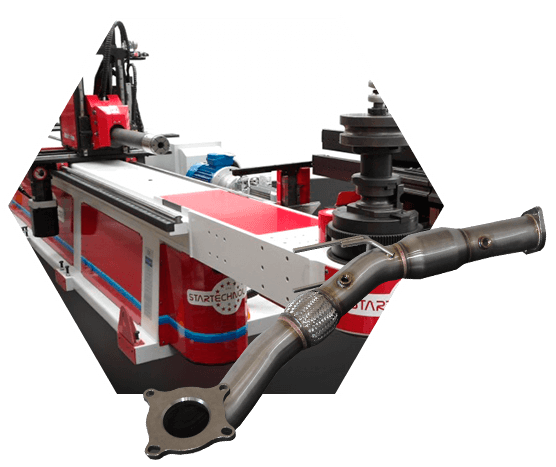

Bending of tubes

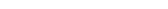

Welding

Types of welds:

TIG Welding

TIG Welding Micro-wire welding

Micro-wire welding Welding with MIG electrode

Welding with MIG electrode Argon

Argon Arc

Arc Aluminum

Aluminum

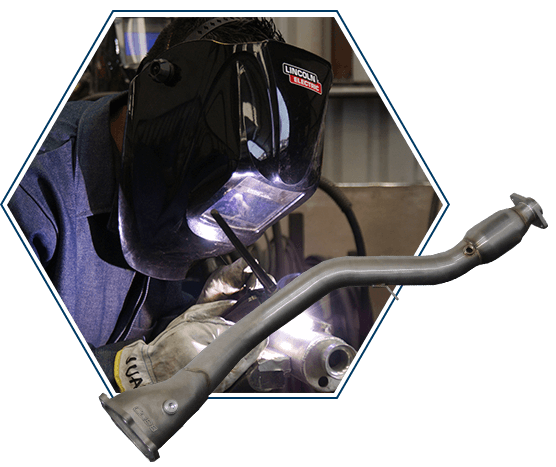

Electro-punching

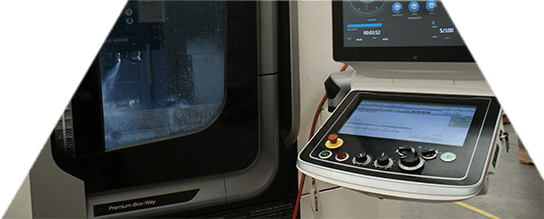

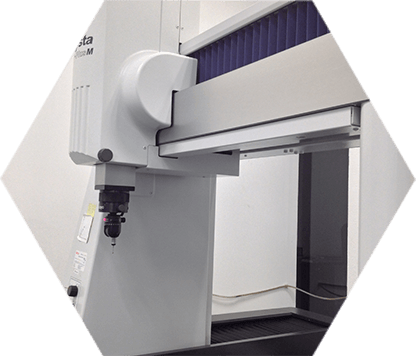

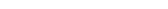

Assurance of product quality

As a continuous supplier to the automotive industry, we face different demands, specifications and volumes every day, therefore, it is essential to ensure the quality of the products and our customers benefit from this. This is complementary to each of the processes to ensure compliance with our customers' specifications.

We can offer in the industry:

Confidence, compliance in specifications as well as quality and innovation in our methods to ensure compliance with your requirements.

We have the best team:

CMM (automatic coordinate measuring machine)

CMM (automatic coordinate measuring machine) Optical comparator

Optical comparator Handyscan 700

Handyscan 700 Custom Tooling

Custom Tooling Saline chamber

Saline chamber Tools of quality assurance in coatings (Brillometer, hardness, colorimeter and thickness)

Tools of quality assurance in coatings (Brillometer, hardness, colorimeter and thickness) X-RAY thickness measuring system

X-RAY thickness measuring system

Nickel Electroless

The electrolytic nickel coating consists of an alloy of nickel phosphor on a metallic substrate without using the electric current.

The chemical reaction creates a uniform coating on complex geometries and has a great resistance to corrosion and wear.

In automotive components, it is used for protection in pistons, gears, injectors, cylinders, among others.

It can be applied on a wide variety of materials:

Aluminum

Aluminum

Stainless steel

Stainless steel Copper

Copper

Brass

Brass

Proprietary alloys

Proprietary alloys